Sustainable fish waste treatment in recirculating aquaculture algae systems

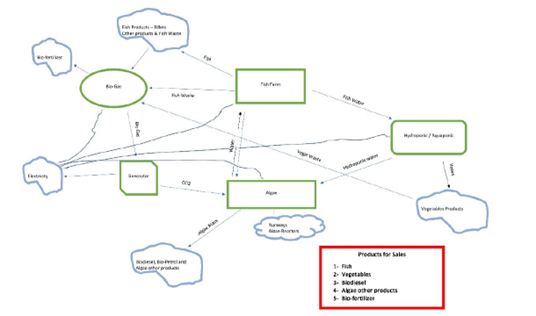

The purpose of this research project is to integrate three food production methods with on another to reduce the cost and the carbon footprint made by them on an independent platform. The first system is related to the agriculture sector, which is a hydroponics setup, second and third systems is related to aquaculture, which is algae and fish farming setup.

Human living space and food supply are competing in across the globe. Food supplies are shortening and living space is increasing. The demand for water and food supplies is increasing. In many places in around the world, the use of current agricultural practises is becoming outdated, and the costs of operating these practises are also affecting the cost of cultivated crops in the country. Due to the employment of antiquated techniques to create numerous goods related to agriculture, construction, and industry, many countries have a very high environmental impact from carbon dioxide and many other greenhouse gases. To manufacture the food and chemicals, the proposed system will almost certainly emit no carbon dioxide and relative gases. The environmental project uses significantly less water and land to produce meat, vegetables, flowers, grains, and animal feed. The yield per acre of land in the proposed project is higher than that of the traditional methods used to produce these important elements of human and animal diets.

Background

Hydroponics technology is being developed to reduce installation costs so that more farmers may afford to raise vegetables and fruits. Currently, the cost of establishing a hydroponics farm is too expensive, and most small-scale farmers cannot afford the initial investment. Hydroponics need a proper management system to monitor, control, and produce the intended results. This management system requires personnel who have the requisite knowledge and understanding of traditional and modern agricultural methods and techniques that farmers employ to efficiently run the hydroponics system. In terms of percentage, a hydroponics system produces vegetables at a rate that is 30-50 percent faster than a conventional system. Many small or even major landowners and farmers in countries such as Pakistan, Afghanistan, and Iran are aware of hydroponics but unable to afford, believing that such technology does not will be expensive to install, and moreover that fruits and vegetables cannot be grown using such methods. Hydroponics technology can assist humanity in combating the future food deficit that the world will face.

The BIOFLOC aquaculture system is a mature technology in terms of its development, progression, and contribution to the aquaculture sector. The technology is cheap to install on a small scale, but on a large scale it can get expensive, especially for the low-income individuals living in Pakistan, Iran, Afghanistan, etc. BIOFLOC produces fish as a source of protein for human consumption at a much lower rate than conventional fish farming in Pakistan because it uses less land, less water, and high stocking densities for high production. Due to high densities, the water quality is affected, and when it is discharged into the sewage system, it could severely affect the natural environment of the water bodies of a country. The costs of energy could be higher than expected for the system, and the yield may not be consistent between seasons. The producers must be actively present at the site during system operation to prevent any abnormalities in water quality and fish behaviour. This active presence at the site will raise the system’s operating costs.

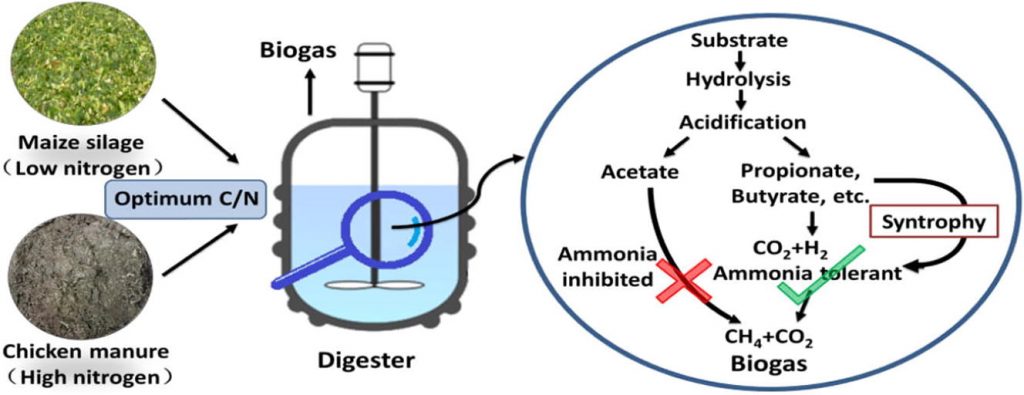

The cultivation of algae has constantly been researched for the purpose of replacing fossil fuels with biofuels. Biofuels are a great alternative to fossil fuels because the current infrastructure is unaffected by the transition to biofuel, but the problem is that to produce biofuel, the cost is significantly higher than the market price of petroleum products. The types of biofuels that can be produced from the cultivation of microalgae are biodiesel, biogas, biohydrogen, bioethanol, and syngas. Each type of these biofuels is used in different types of engines to produce mechanical or electrical energy to facilitate human progress in science and technology. The microalgae use photosynthesis to convert carbon dioxide and industrial waste into biomass that can be used to make useful products such as biofuel. The algae cultivation is therefore a carbon-neutral project because it uses carbon dioxide as a source for the microalgae to grow. The international price of diesel is around 72 dollars per barrel; on the other hand, the cost of producing biofuel is around 140–900 dollars per barrel, which is at least twice the market price of fossil fuel, which is not attractive for many individuals and families.

Gap analysis

- Integrating each of these setups together to use the fish and plant waste as by-product for the system.

- The cost of operation and production is high.

- Fish waste is not used as a fertilizer for algae so it can be produced.

- Hydroponic, Algae, and Fish farming can be linked together to grow cheaper food and meet the energy requirements of the system almost free.

- Can other technologies such as biogas and solar to further reduce the cost to energy inputs to the system.

Layout

Preliminary Design

Overall Design

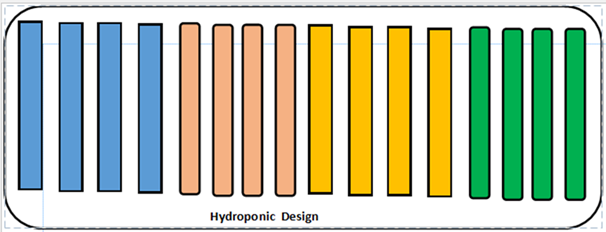

Hydroponics

BIOFLOC

Algae

Description

Overall Design

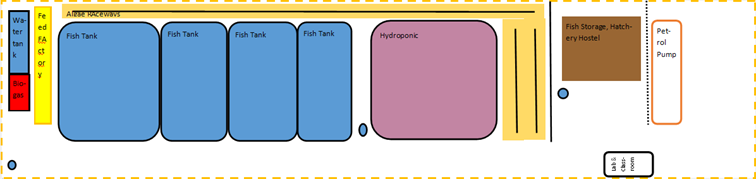

- The available land and its size for the overall design is 1100 ft by 100 ft.

- Location: Samundari, Faisalabad District, Punjab, Pakistan.

- Biogas will be used to provide electricity for the whole project.

- The integration will be from that water will circulate from fishpond to hydroponics to algae ponds.

- Excess water will be directly transferred to fishpond to algae ponds.

- A building will be constructed for processing fish and vegetables.

- The same building will also have hatchery for new fish seed.

- All the vegetable waste and fish waste will be directly transferred to biogas system for the purpose generating gas.

- The filtering system will filter any small debris or unwanted solids in the water that are harmful to the aquatic life in the ponds.

- The algae harvesting system will also be installed near the controls and monitoring system are of the project.

- Monitoring systems for monitoring the water quality and plant health will be installed so maximum yield can be achieved with high quality produce.

Results

Hydroponics

| Hydroponic Type | Sizes in ft | No. of Rows | No. of Vertical Rows | No. of Plants | Estimated Production |

| Vertical | 1.5 x 72 | 6 | 9 | 15500 | 5 Ton |

| Tri Shape | 4 x 72 | 5 | 30 | 21000 | 8 Ton |

| Potato & Tomato | 2 x 72 | 7 | 1+1 (P&T) | 1500 -P 1500-T | 15 Ton – P 45 Ton – T |

| Plants | 30 X 72 | 30 | – | 2160 | – |

BIOFLOC

| Detail | Tank Size in Ft | Tank Depth Ft | Litre Water | No of Fish | Estimated Production |

| Tank – 1 | 60×70 | 10 | 1,050,000 | 25,000 | 50 Ton |

| Tank – 2 | 100×70 | 10 | 1,764,000 | 41,000 | 82 Ton |

| Tank – 3 | 100×70 | 10 | 1,764,000 | 41,000 | 82 Ton |

| Tank-4 | 200×70 | 10 | 3,528,000 | 75,000 | 150 Ton |

| Total | 8,106,000 | 182,000 | 360 Ton |

Algae

| Algae System | Size in ft | Depth in ft | Wide in ft | Algae (grams/litre) | Total Algae (Kg/day) |

| Raceways | 660 x 4 | 2 | 2 | 0.01 | 490 |

| Bioreactors | 40 x 80 | 4 | 3 (Dia) | 0.02 | 1013 |

Results (Product, Technology, Customer, Competitor, SWOT analysis, Mass scaling in Commercially)

HSF uses cutting-edge search technology that is currently in use in advanced nations on a big and commercial scale, but HSF wants to transform expensive high-tech into something that is affordable in developing nations, taking into account local environmental factors. As a result, HSF and the university share responsibility for finding ways to transfer advanced technology so that poorly educated farmers and small landowners can profit from it.

Hydroponic is producing 50 times per plant rather than conversional way, i.e., The yield of dry chillies of rain fed crop is 200 – 400 kg and that of irrigated crop is 600 – 1000 kg per acre and having 22200 plants in an acre but in hydroponic is produce 33 tons as same no of plants. Hydroponic uses 90% less water, having technique to grow large food which is already having shortage in the world. This method of agriculture is producing organic and pesticide free. Other benefits are Extend grow season, improve growth and yield, Higher plant density, Plants can grow anywhere, less water consumption, and Easier to harvest mature plants and disadvantage are Expensive to set up, Vulnerable to power outages, require constant monitoring & maintenance, Waterborne diseases and removing problem affect plants quicker.

Fishing in Conversional Method having less than Bio floc i.e., This hardy fish has high stocking density and even without aeration 6,000- 7,000 of Tilapia can be stocked per acre as compared to the Conventional Carps having the density of 600-1,200 per acre but in bio floc is 40 litre water per fish and really great water saving. It has the following benefits, Eco-friendly culture system, reduce environmental impact, water use efficiency, zero water change, Higher productivity, Higher biosecurity, reduces water pollution, and cost-effective feed production, and following disadvantage is increased energy requirement for mixing aeration, Alkalinity supplementation required, Increased pollution from nitrate accumulation, inconsistent and seasonal performance for sunlight exposure.

Algae is by-product of fishing water, and We can grow algae strains in almost any climate thanks to the open- or closed-tank approaches that are available today. As long as we can provide this natural product with enough sunlight to create photosynthesis, then it has the capability to grow quickly. The advantages of Algae biofuel is grown at higher efficiency levels than other fuel crops, is more productive than other forms of biomass, renewable resource, produces viable hydrocarbons for numerous products, something that almost anyone can grow, grows in virtually all waters, biofuels work with our current distribution system, growth helps us to curb our greenhouse gas emissions, and disadvantages Algae has the same concerns of monoculture that the agriculture industry experiences, growth may create quality variations during the refinement process, Algae biofuel doesn’t always meet its energy efficiency targets, growth creates regional sustainability problems, it might grow quickly, but it still needs time to produce viable oils, biofuels come with higher production costs, growth requires high levels of fertilizer to maximize production, and contamination occurs more often with large-scale production methods.

In Pakistan, HSF doesn’t have any rivals in the market or the sector of industrial search. The business plans to launch this project on a broad scale for commercial purposes. The daily production of 10K liters each of bioethanol and biodiesel is the goal of HSF. HSF needs to create 20K kg of algae, which requires 10M liters of grower algae water every day. Similar to the conversational method, hydroponics will produce 30 to 50 percent more.

Results (Tech Development, Transfer, Standardization, Licensing, and Commercialization)

HSF intends to register its trademark in the nation, transfer its technology there, build up its own standards for the products, and create user manuals, setup manuals, and technical data sheets. HSF will keep looking for ways to improve its own goods and move the search for the following steps forward.

The actual concept behind this search is that the bank defaults, empty warehouses, and closed industries of the nation will utilise our search goods to update themselves on the market. They can use hydroponic techniques to grow veggies, medicinal flowers, and other types of expensive food. The chicken and egg production sector can use biogas techniques to become a self-sustaining enterprise that is not dependent on the purchase of electricity. To cultivate algae to produce biodiesel and bioethanol, industry roofing can be used.